-

-

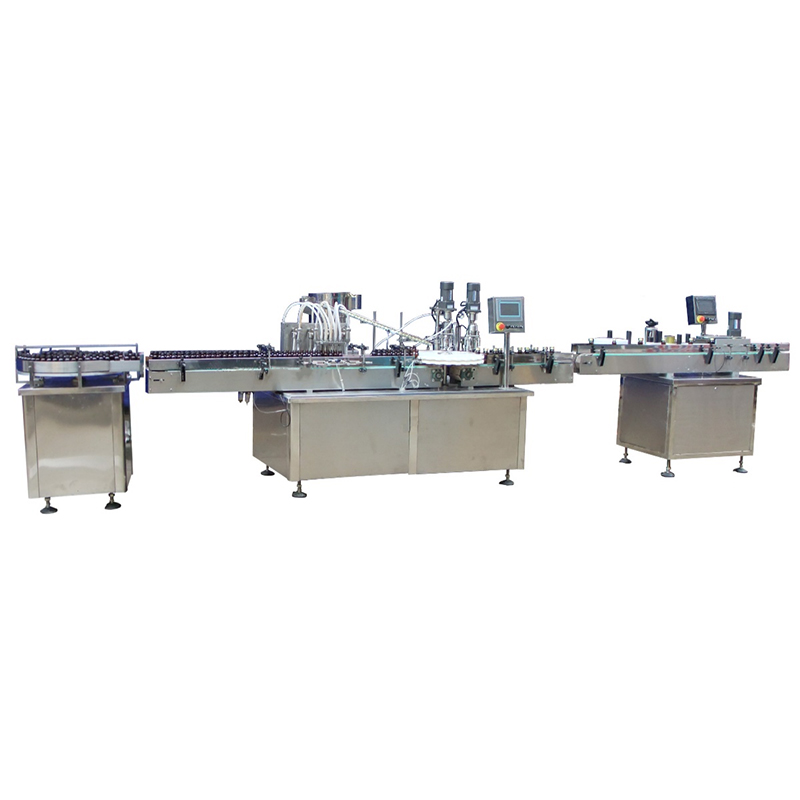

Automatic tablet capsule counting line

Automatic tablet capsule counting line

Tablet/capsule counting line is mainly made up of round bottle unscramble, electronic counting machine, automatic desiccant inserter (cotton inserter). Automatic capping machine, induction sealer and round bottle labeling machine.

BOTTLE UNSCRAMBLER

The block bottle device on the passing bottle-track of the conveying bottle system make the bottles which came from the previous equipment stay in the bottling position, waiting to be filled in. The medicine goes into the medicine container in order by the vibration of the feeding corrugated plate. There’s a counting photoelectric sensor installed on the medicine container, after counting of the medicine in the medicine container by the counting photoelectric sensor, the medicine goes into the bottle in the bottling position.

Feature

(1) It is the mechanical-electrical integration equipment with convenient operation, easy maintenance and reliable operation.

(2) Installed with device of control and testing certain quantity of ready bottles and the protection device of excessive overloading.

(3) The frame and the bin are made of good stainless steel with nice appearance and it conforms to the GMP requirement.

(4) Blowing bottles with air pressure is not necessary and there’s the device of turning bottles automatically and the device of bottle collecting.

Technical Parameter

Applicable bottle type | Plastic round bottle |

Production capacity | 30~120 bottles per minute |

Power supply and power: | AC220V 50Hz 0.25kw |

Dimensions | 1200×1150×1300mm |

Weight | 120kg |

ELECTRONIC COUNTING MACHINE

Overview

Electronic counting machines, which are a stable reliable electronic product that was successfully developed through repeated experiment after long-time research. Its core part and control system adopt imported accessories. It mainly consists of such structures as hopper vibration transmission, photoelectric sensor, dust storage box, human computer interface.

Main features

l Wide applicability: used for tablets including abnormal tablets), capsules, gels (including abnormal gels, transparent gels and opaque gels), pills and most solid granules.

l Anti-dust: using high anti-dust sensor technology, the machine works accurately with good stability in heavy dust conditions

l Avoid the materials jam: hopper mouth of special structure, to prevent the material jam, small mouth bottle can quickly bottling

l Feeding evenly with quiver, special patent filling part, no breakage of the material

l Detection function: no bottles will not count and fill. Automatically remove bottles of filing abnormalities Self- diagnose errors and stop working to make alarm at errors.

Main technical parameters

Model | JF-8A | JF-12A | JF-16A | JF-24A | JF-32A | JF-48A |

| JF-8B | JF-12B | JF-16B | JF-24B | JF-32B | JF-48B |

Applicable | Model A: 0~5# capsule、soft capsule、 Φ5.5~12 normal tablets、special shape tablets、 coating tablets. |

| Model B: 00-5# capsule、soft capsule、<Φ22 normal tablets、special shape tablets、coating tablets、Φ3 ~ 20 pills |

Capacity | 10-30BMP | 20-40BMP | 20-80BMP | 20-90BMP | 40-120BMP | 40-150BMP |

Working range | Adjust from 2-9999 per bottle |

Power supply | 220V/50HZ/0.6kw | 220V/50HZ/0.8KW | 220V/50HZ/1.2KW | 2220V/50HZ/1.5KW | 220V/50HZ/2.2KW | 220V/50HZ/2.5KW |

Overall dimension | 1360*1350*1650mm | 1360*1350*1650mm | 1360*1350*1650mm | 1760*1350*1650mm | 2160*1350*1650mm | 2160*1450*1650mm |

| 1360*1650*1650mm | 1360*1650*1650mm | 1360*1650*1650mm | 1760*1650*1650mm | 2160*1650*1650mm | 2160*1650*1650mm |

Weight | 250kg | 320kg | 420kg | 450kg | 550kg | 620kg |

| 300kg | 380kg | 550kg | 580kg | 620kg | 680kg |

Remarks | 1. Capacity is subjected to the type and the size of the bottles and tablets, as well as the quantity filled per bottle;2.BMP=Bottles per minute |

DRYING AGENT FILLING MACHINE

Feature

(1) Strong compatibility, suitable for round, oblate, square and flat square bottles of various specifications and materials.

(2) Desiccant bag packed in a disc-shaped bag with or without color code;

(3) The design of pre-loaded desiccant belt is adopted to avoid uneven delivery of bags and ensure the accuracy of bag length control.

(4) The desiccant bag thickness self-adaptive design is adopted for the bag to avoid bag breakage during the transfer process.

(5) Highly durable knife edge, accurate and reliable cutting, will not cut the desiccant bag;

Technical parameter

Applicable bottle shape | Round、oblate、square、flat square bottle |

Drying agent bag | Plate shape drying agent, the bag size is depended on the bottle size |

Production capacity | 50~120 bottle/minute |

Power supply and power | AC220V 50Hz 0.5kw |

Dimension | 1600×750×1780mm |

Air pressure | 0.6Mpa |

Weight | 180kg |

CAP SCREWING MACHINE

(1) Strong compatibility, suitable for plastic caps and bottles of various specifications;

(2) Capping torque control to ensure the quality of capping

(3) It stops working if no bottle or no cap. Detecting and rejecting of crooked cap, reverse cap and no aluminum foil, and fault self-check etc. multiple inspection and alarm control functions to ensure continuity and accuracy;

(4) Fully automatic operation, intelligent joint control with upper and lower processes, good coordination, saving labor;

Technical Parameters

Type | JF-D902 | JF-D903 |

Applicable objects | Ordinary cap, cap with protective ring, double layer cap, flip cap and other plastic caps. |

Output | 50-120 bottles/min | 60-180 bottles/min |

Power supply | 220V/50Hz/1.5Kw | 220V/50Hz/1.8Kw |

Pressure | 0.6Mpa | 0.6Mpa |

Consumption air | 0.3 m³/h | 0.3 m³/h |

Dimensions | 2550*1050*1900mm | 2550*1050*1900mm |

Weight | 650 | 680 |

ELECTROMAGNETIC ALUMINUM FOIL SEALING MACHINE

The bottle with aluminum foil passes under the induction head, and the aluminum foil is heated by the energy generated by the induction head. The heated aluminum foil melts the plastic film compound on the aluminum foil and bonds closely with the bottle mouth to obtain the sealing effect.

Feature

(1) The applicability is strong, and the sealing power can be automatically adjusted according to the size of the aluminum foil;

(2) High electromagnetic conversion efficiency, low energy consumption, and good sealing effect;

(3) If the sealing power is too small or overloaded, prompt promptly and automatically shut down;

(4) Using air-cooled cooling, the effect is good;

Technical Parameters

Output (pcs/min) | 50~120 bottles/min |

Applicable bottle type | 15~500ml round, oblate, square, flat square bottle, bottle mouth diameter 15~45mm |

Air source | 0.6Mpa |

Power supply and power | AC220V 50Hz 2.5kw |

Weight | 100kg |

ROUND BOTTLE LABELING MACHINE

The bottles that need to be labeled are conveyed by the bottle feeding track, through the bottle spacing adjustment mechanism, the bottle is separated by equal distance. The photoelectric sensor senses the passing bottles and sends out a signal. The transmission system is activated by the signal and starts to send the label. The tensioning system realizes the labeling.

Feature

(1) Strong compatibility, suitable for various round objects;

(2) Adopting compacting labelling design, it can ensure the quality of labelling and can control the length of the label paper and the uniformity of labelling starting

(3) Adopting pre-labelling system, labels come out stably with good smoothness of label sticking and high accuracy of positioning

Technical Parameter

Output (pcs/min) | 20-120 (depends on bottle and label size) |

Label type | Self-adhesive label, opaque |

Applicable bottle type | 15~500ml round bottle |

Air source | 0.6Mpa |

Voltage | AC220V 50/60HZ Single phase |

Power | 0.15KW |

Weight | 150kg |

<< Previous Page

Next Page >>

related products

+86 - 0419 - 2305869

+86 - 0419 - 2305869

frank@pharmao.com

frank@pharmao.com

chinapharmao

chinapharmao

Emma_Wong_

Emma_Wong_