-

-

Automatic Powder Granule Filling Production Line

Automatic Powder Granule Filling Production Line

This production line is suitable for filling powder or granule into bottle

The body material of this machine is made of high quality stainless steel, other parts are also made of non-toxic and durable series materials, the equipment failure rate is low, high reliability.

Turntable diameter 800mm, suitable for round bottle diameter 40-130mm, height 30-200mm, can be customized according to customer requirements, the price is negotiable.

The fastest production efficiency can reach 45 bottles / minute.

The size of the equipment is about 1 * 0.8 * 1.2 m (LxWxH)

Net weight is about 50KG

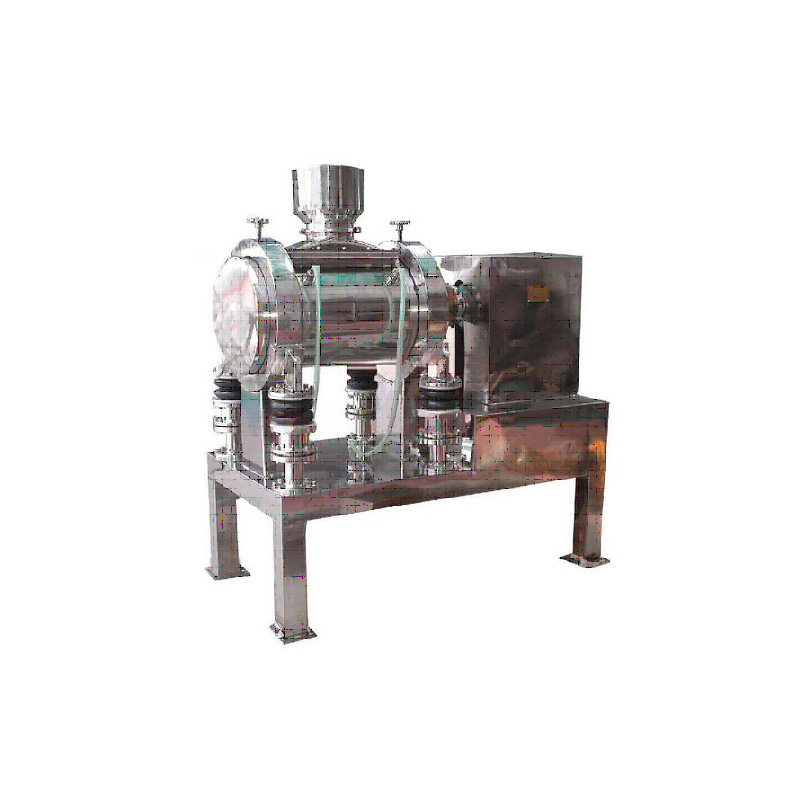

LINEAR SINGLE HEAD POWDER FILLING MACHINE

Performance description

1. The overall appearance material is covered with stainless steel 304 sheet

2. The plexiglass material is made of transparent acrylic.

3. Adopt PLC intelligent programming and touch screen manual operation control system

4. 304# stainless steel structure, horizontal open type transparent material box, can be disassembled and cleaned without tools, easy to clean.

5. Equipped with a dust removal device and connected to a negative pressure pipeline, which can effectively absorb the powder flied during the filling process and effectively protect the workshop environment.

6. Added bottle blocking detection for bottle output, including bottle blocking pause function, convenient to connect to automatic filling production line, and smooth control.

7. According to the filling capacity or fluidity of powder materials, the screw or the discharging port needs to be replaced. The replacement time is about 20-40 minutes; the height of the bottle does not need to be replaced, and the whole filling head is designed with a hand screw. Adjust up and down, the adjustment time is about 10-30 minutes;

8. The replacement of screw can measure different weight and precision, and is suitable for automatic filling of various powdered materials such as milk powder, protein powder, Chinese medicine powder, health products, chicken powder and other condiments, snack foods and other powder products;

9. This machine needs to be equipped with additional compressed air source: the gas output is 0.25 cubic meters per minute or 2.2KW, the buyer shall prepare the compressed air source, and the compressed air pressure:0.6-0.8MPa.

Technical parameter

1. Production capacity:15~25 bottles/minute

2. Packaging weight: 10-100g. Material bin: 30L

3. Packaging accuracy: 10-100g≦±0.5-3g (different materials will have different errors)

4. Measurement method: single-head screw volumetric

5. Screw feeding machine hopper: 200L (Option: vacuum feeding machine)

6. Filling cans/bottles have a diameter of φ40~φ130mm and a height of 60~200mm (beyond this range, customization is required);

7. Main machine total power: 2.1KW/380V, screw feeder power: 2.24KW /380V, total power: 4.34KW;

STANDARD 10-HEAD COMPUTER COMBINATION WEIGHING MACHINE

Scope of application

Suitable for weighing and packing of granules, flake and strip shape materials.

Technical Parameters

1. Weighing range: 10-1000g

2. Weighing accuracy: ±0.5-2g (the accuracy is related to the material)

3. Weighing speed: 15-25 cans/min.

4. Hopper capacity: 1.6L

5. Drive mode: stepper motor

6. Weighing head size (mm): L1130*W1080*H1420

7. The net weight of the weighing head: 250KG

8. Z elevator size (mm): L3165*W650*H3700 (the height can be made according to your company's size requirements)

9. The net weight of the Z elevator: 300KG

10. Platform size (mm): L2000*W2000*H1800*1000 (column height)

11. The net weight of the platform: 200KG

12. Overall dimensions after combined installation (mm): L2200*W4000*H3500

ROTARY PLATE GRANULE RECEIVING MACHINE

Echnical Parameters

1. Filling diameter φ40~φ130mm, applicable height 50~200mm (customized according to the bottle size)

2. Turntable stations: 10 stations (the design may be changed according to the actual situation)

3. The production efficiency: about 20-30 bottles per minute;

4. The overall appearance material is mainly made of stainless steel 304 with a thickness of 1.5mm;

5. The chuck and receiving hopper need to be replaced to replace the blanking diameter. The replacement and debugging time is about 10 minutes;

6. Change the height of the tank without changing accessories, just shake the hand wheel, the range is controlled by 50-200mm, and the adjustment time is about 5 minutes;

7. Conveyor belt motor 0.2KW*2, stepper motor power 0.55KW, total power 0.95KW, single-phase 220V motor;

8. Air source configuration: about 2 cubic meters per minute, 0.6-0.8Mpa, air source or air pump is used as auxiliary equipment, and relevant auxiliary equipment needs to be prepared by user locally;

CAPPING MACHINE

Technical parameters

1、 Cap diameter φ30~φ80mm, cap height minimum 10mm (customized according to actual needs).

2、 Production efficiency 20-40 bottles/ minute.

3、 The capacity of the hopper of the cap elevator is 150L.

4、 The overall appearance of the material is mainly made of stainless steel 304.

5、 If the mouth diameter is different, it needs to replace the cap groove, as well as adjust the cap elevator and cap wheel, the adjustment time is 30 minutes.

6、 To change the height of the bottle, adjust the capping head by hand cranking the screw lever, the adjustment time is about 5-10 minutes.

7、 The size of the equipment is about: 3.00m *0.90m *1.6m

8、using PLC intelligent program design plus touch screen control, easy to use and simple to set up.

9、Power: 2 x 0.12KW clip spin motors, 2 x 0.12KW clip belt motors, 1 x 0.37KW conveyor belt motor, Total power 1.22KW.

10、Strong applicability, can be applied to common round cap, high round cap etc.

11、The machine needs to be equipped with air compressor (prepared by user), and the pressure of air source is 0.5-0.7MPa.

ELECTROMAGNETIC INDUCTION ALUMINUM FOIL SEALING MACHINE

Technical parameters

1. Sealing diameter: 50-121mm; larger mouth diameters can be equipped with enlarged sealing heads and need non-standard customization (Option)

2. The production efficiency is about 30-200 bottles/min

3. Rated voltage AC 220V 50/60Hz, power 4000W;

4. The dimension of the main machine is 950*310*420mm, the external dimension of the independent lifting frame is 1440*460*310mm

5. Net weight is about 55KG

6. Aluminum foil requirements: the material of aluminum foil corresponds to the material of the can (for example: PET film for PET cans, PE film for PE cans), thickness of aluminum foil: 0.1-0.4MM

7. Working principle and method: The aluminum foil needs to be placed inside the cap in advance. After the cap is screwed, the lid presses the aluminum foil on the bottle. When the can passes through the equipment, the aluminum foil is heated by electromagnetic action to make the aluminum foil stick to the bottle mouth;

8. Over current and over voltage, automatic protection, safe and reliable;

9. Cooling method: air cooling; split type with independent lifting frame, air cooling, performance close to the effect of water-cooled machine;

10. The main material of the appearance of the main machine is SUS304 stainless steel; the standard machine does not have a conveyor belt, and it needs to be purchased additionally.

ROUND BOTTLE LABELING MACHINE

Equipment composition

Electrical cabinet, conveying mechanism, separate bottle device、roll label device、brush label device、labeling engine、operation system and control system; Ribbon printer can be optional

Working process

Bottles move to separate bottle device for separation, keep bottles in a certain distance and move in a center line;

When sensor check bottle, it sends signal to PLC, PLC received the signal deal with information first, then output signal to motor driver, driven by the drive motor for send label.

The brush label device past label on bottle one side first, then bottle rolling around in the roll label device, brush label on bottle body for around, labeling finish.

Technical Parameter

Output | 20-120pcs/min (depends on bottle and label size) |

Label type | Self-adhesive label, opaque |

The inner diameter of label roll | 76 mm |

The outer diameter of label roll | 300 mm(max) |

The suitable size of label | Width (backing paper) 15-150 mm length 15-230 mm |

The suitable size of labeling objects | Diameter 20~100mm |

Printer use air | 5kg/cm² |

Voltage | AC220V 50/60HZ Single phase |

Power | 800W |

Weight | 200kg |

<< Previous Page

Next Page >>

related products

+86 - 0419 - 2305869

+86 - 0419 - 2305869

frank@pharmao.com

frank@pharmao.com

chinapharmao

chinapharmao

Emma_Wong_

Emma_Wong_