- Home

-

About Us

-

Products

-

RAW MATERIAL MACHINERY

●Powder milling equipment

●Sifter machine

●Powder mixing equipment

●Granulating machine

●Drying equipment

-

TABLET MACHINE

●GZPK370 high speed tablet press

●GZPK720 high speed tablet press

●Sub-high speed tablet press

●Medium speed tablet press

●3 layer dishwasher tablet press

●2 layer rotary tablet press

●Effervescent tablet press machine

●Intelligent EU tooling rotary tablet press

●Mini rotary tablet press

●Tablet deduster

●Tablet coating machine

-

CAPSULE FILLING MACHINE

●Semi automatic capsule filling machine

●Automatic capsule filling machine

●Softgel encapsulation machine

●Capsule polisher

-

PACKING MACHINERY

●Sachet packaging machine

●Pouch packaging machine

●Blister packaging machine

●Deblistering machine

●Semi automatic powder filling machine

●Automatic powder granule filling production line

●Desktop tablet capsule counting machine

●Automatic tablet capsule counting line

-

LIQUID FILLING MACHINE

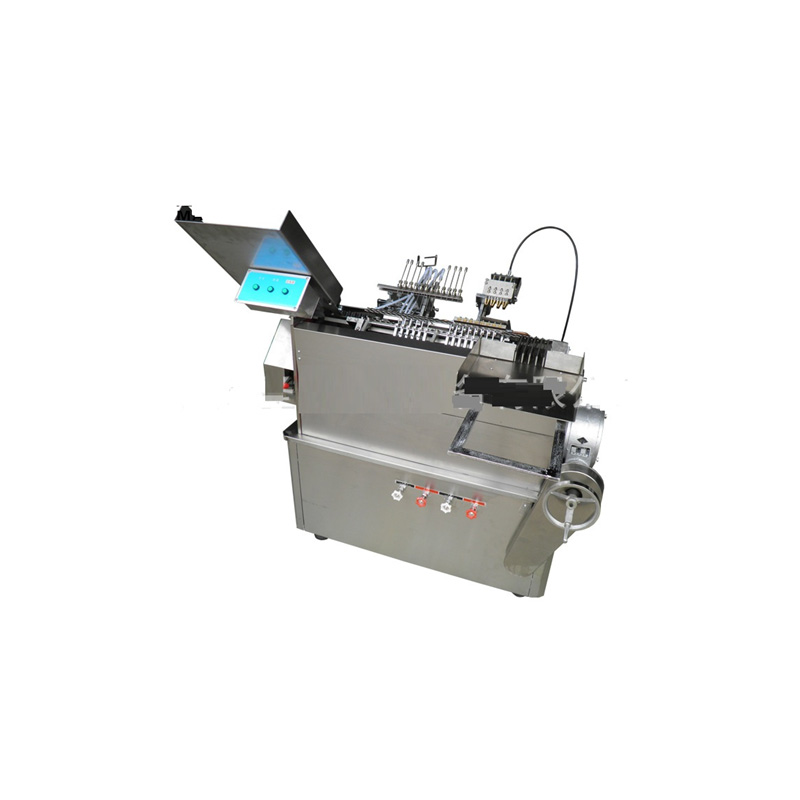

●Ampoule filling and sealing machine

●Liquid filling line

●Semi automatic aerosol filling machine

-

OINTMENT, SUPPOSITORY MACHINE

●Vacuum emulsifying mixer

●Tube filling and sealing machine

●Suppository filling machine

-

LABORATORY INSTRUMENT

●To: www.chinapharmao.com

-

-

News

-

Contact Us

- HOME

- About Us

- Products

- TABLET MACHINE

- GZPK370 high speed tablet press

- GZPK720 high speed tablet press

- Sub-high speed tablet press

- Medium speed tablet press

- 3 layer dishwasher tablet press

- 2 layer rotary tablet press

- Effervescent tablet press machine

- Intelligent EU tooling rotary tablet press

- Mini rotary tablet press

- Tablet deduster

- Tablet coating machine

- CAPSULE FILLING MACHINE

- Semi automatic capsule filling machine

- Automatic capsule filling machine

- Softgel encapsulation machine

- Capsule polisher

- PACKING MACHINERY

- Sachet packaging machine

- Pouch packaging machine

- Blister packaging machine

- Deblistering machine

- Semi automatic powder filling machine

- Automatic powder granule filling production line

- Desktop tablet capsule counting machine

- Automatic tablet capsule counting line

- LIQUID FILLING MACHINE

- OINTMENT, SUPPOSITORY MACHINE

- LABORATORY INSTRUMENT

+86 - 0419 - 2305869

+86 - 0419 - 2305869

frank@pharmao.com

frank@pharmao.com

chinapharmao

chinapharmao

Emma_Wong_

Emma_Wong_